Finding that perfect surfboard is easier said than done as the generic factory-made boards most likely won’t meet your unique surfing needs. Just as some teenagers need their prom dress to be tailored to suit their unique body shape or some car fanatics want their car to stand out with a special bumper or custom artwork, so do some surfers require their boards to be a bit more unique.

So, if you’ve already tried every board in the shop, it might be time to think about getting in touch with your local surfboard builder and let them construct your custom board.

For hundreds of years, surfboards were constructed from nothing but wood, with the board stained with natural plant oils. They were big, heavy, and plain-looking.

In modern times, boards are made from various materials to help withstand the force from the waves and although various materials go into the making of a surfboard, it still needs to be light, buoyant, and strong.

Let’s delve into the bigger questions; how exactly is a surfboard made? What materials are used? How does it get its shape? How can it withstand the force of the waves?

Follow along as we take a behind-the-scenes look at how a modern-day surfboard is made in this interview with hand shaper Lyndon Read from Lyndon Read Surfboards.

Manufacturing Process

Client Brief

Most projects begin with a brief. In this case, the shaper and client would meet to discuss the specifications for the build of the board. Not only are the board dimensions discussed but also the surfer’s body dimensions, stance, experience level, and types of waves to be surfed.

Below, Lyndon takes a look at a form filled in by a client on what exactly they want to have in their surfboard. The form includes fields like tail shape, rail type, length, width, and thickness of the board, etc.

Basic Canvas

In order to start building the surfboard, the shaper makes use of a moulded piece of foam called a “blank”. This will be the core of the surfboard that will be shaped, glassed, and polished resulting in a finished surfboard.

A blank is roughly formed in a surfboard-shaped blown mould. Inside the mould, polyurethane chemicals are poured which forms a thick, white foam resulting in the “foam core”.

Commonly the blank is made of two foam halves, running from the nose to the tail. Sandwiched between these halves is a thin wooden stringer (about 5 mm wide) which helps provide strength to the board but still allowing flexibility.

Shaping

Using an electric planer, the shaper uses his trained eye to remove excess foam from the blank until it is the ideal thickness. Constantly refining the contour and ensuring there are no uneven bumps on the surface of the board.

See as Lyndon planes the blank below with an electric planer.

When the board is the right thickness, the surfboard builder then uses a hand plane and sandpaper to further shape the board’s surface and sides.

Below are a few shots of Lyndon checking the board’s thickness and further smoothing it down by hand.

According to Lyndon, what makes his work different than other shapers, is that he makes use of multiple shapes to create a new, unique shape for his clients.

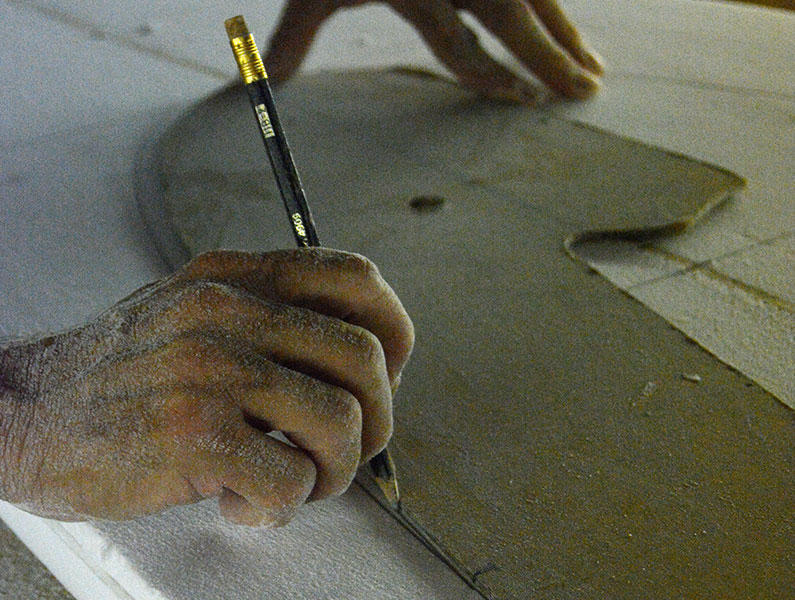

Below you can see him make measurements for when he needs to start cutting out the board. The board needs to be a length of 5’11” and a width of 19”, which was specified by the client on the order form.

After all the measurements are done, Lyndon starts cutting out the board with a hand saw. This is a tiring job and can become quite tricky when it comes to the head and tail areas.

After the cutting process, the board is then smoothed down again to get rid of the rough bumps created by the saw.

Below you can see the blank taking its final surfboard shape.

Personalisation

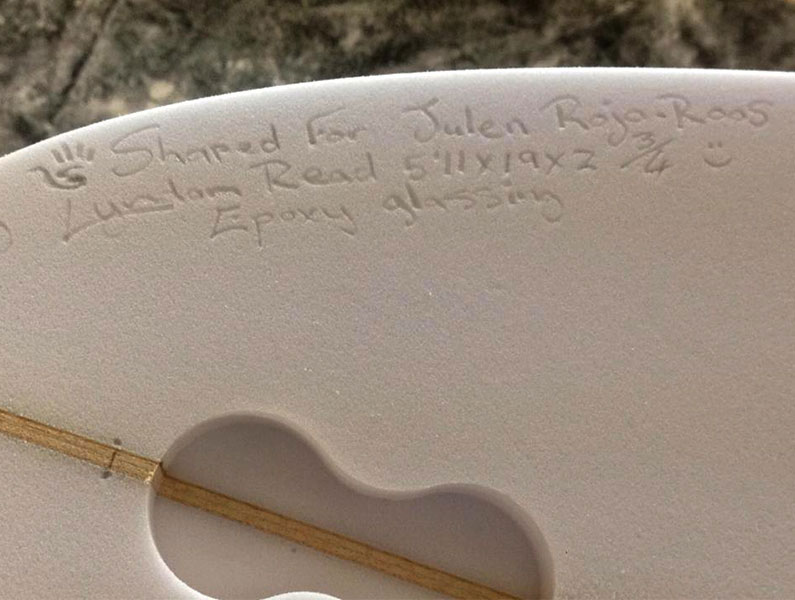

Before the final stage of glassing comes into play, the board builder will typically add personalisation to the board to make it more unique for the client.

Lyndon typically adds his signature to the board along with other details like the client’s name, the date the board was created, its size, and also what type of glassing is used.

Glassing

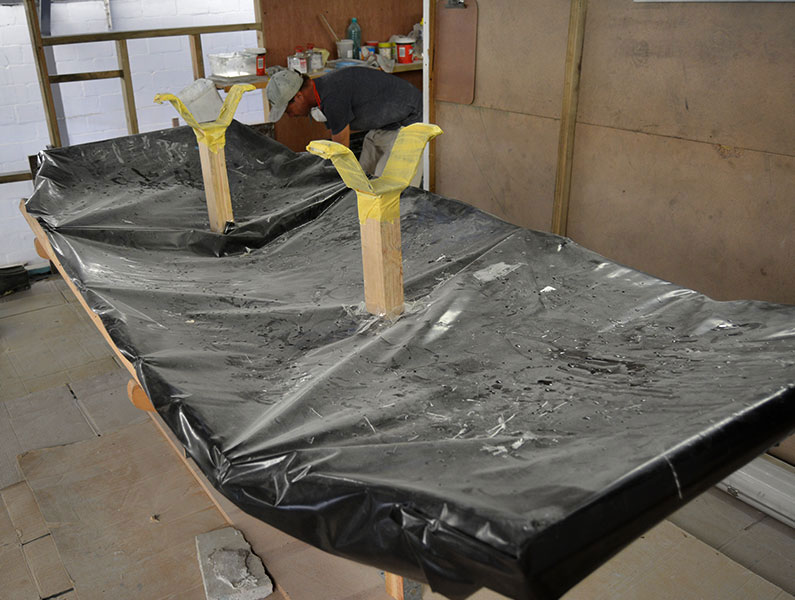

The next part can become quite a sticky mess. “Glassing” refers to the whole process of sealing the core of the surfboard with fibreglass and resin.

The first step is laminating the foam core with fibreglass cloth and resin. Board builders typically make use of Epoxy resin as it’s less toxic when used to build the surfboard, and it makes the board stronger and more flexible. This type of resin is generally used with EPS foam cores but is also used on foam cores containing Polyurethane.

Below is the space where Lydon places a board that’s ready to be glassed.

Now that we finally know the process of building a surfboard and what diligent work goes into such a project, follow along our conversation with Lyndon Read, local, handmade-surfboard builder.

Interview with Lyndon Read Surfboards

Why would someone consider a custom-built surfboard over a factory-made one?

“Because they’re looking for a specific requirement from the board. Most of my clients are looking for a very unique board for unique conditions. Some people will want a longboard but a certain type of longboard for Muizenberg. Then they’ll want to use the same board for riding the Inner Kom, which is at Kommetjie. I’ve got to create a board that can actually handle both of those waves. The one is very flat and forgiving, while the other is quite steep, round, and very fast. It’s a little left that runs really quickly and is quite steep. The rails need to be rolled a certain way so that it can handle that wave but then also a pleasure when surfing at ‘Berg.”

Is it difficult making the board work for both situations?

“It is kind of tricky. When you’re shaping you’ve got to mentally simulate the actual riding of the board and how it’ll perform in those waves. That’s what I do with every single board I shape. Sometimes people want a stock standard board with the focus being on custom artwork. But I always do my own tweaking to the shaping of the board.

For a beginner, I will put things in like a big single concave which is almost like training wheels on a bicycle. As they improve, the concave actually starts coming into play. But when they’re still at beginner-level, it actually helps them stabilise.”

What is your ethos for building boards?

“I think I want to achieve the ultimate lifestyle. And that’s the end goal. The ultimate lifestyle would be to travel around locally and internationally, from Cape Town to Durban to Mozambique. I’ve always wanted to go to places like Sri Lanka, Morocco, and Brazil. Ideally, I’d like to create a base in Europe and the States and move between them. I’d like to work as a guest shaper.”

Do you see that happening in the next few years?

“In the next three years, definitely. I’ve already started establishing connections overseas with other shapers who have been asking me to come over. I am committing the next two to three years solidifying my platform here before branching out further.”

How long does it take to build a board?

“It takes about three hours shaping the board, about one to two hours doing the artwork, and about three hours glassing. It can be built in a day but typically it’s about two weeks.”

What are the steps to build a surfboard from scratch?

“The customer will come to me and ask me to make them a board. We then fill out an order form. I ask for full payment upfront upon receipt of my invoice. Once payment is received I schedule the manufacture of their board into my calendar. With this money, I purchase the blank, fibreglass cloth, resin, fin-, and leash plugs along with specifics to the artwork. I don’t supply fins with my boards as these are expensive and often the customer has a preference.

“Once I’ve bought the blank, I start the process of shaping. Followed by artwork, simple artwork can take an hour and a half to two hours, where complicated artwork can take up to four hours to do.”

Do you glass the boards yourself?

“I don’t outsource my boards for glassing and finishing, I do everything myself. I do the entire process from A-Z. In the surf industry, you’ll find that most shapers don’t glass or sand their shapes. With most of the shapers I know, they’ll shape the board and send the board away for artwork or have an artist come in to do it. Then it goes to somebody else for laminating and there’s somebody else who glasses the board. Hopefully, it’s a surfer but generally, it’s not.

There’s a huge technique to glassing a board. When you’re riding a surfboard, and you’re a good surfer, you want your board to flex in certain ways. You want your board to be very responsive under your feet. Most surfboard factories have labourers working that have never surfed in their lives before. They don’t understand the fundamentals of glassing a surfboard. And that’s why, I think, being a custom shaper (custom board builder is actually what I am) is very beneficial to my clients. They’re not getting a surfboard that they can just go buy off the shelf.”

Do you make space for the fins?

“So, you buy things that are called “fin plugs” and then sink them into the board. Then you glass over that.”

What materials do you use?

“There are two types of foams predominantly used; polyurethane and polystyrene. Polyurethane is laminated with polyester or epoxy resin while polystyrene can only be laminated with epoxy resin. When glassing the bottom deck, either a 4 or 6 ounce fiberglass cloth would be used. The top deck would also be glassed with a 4 or 6 ounce fiberglass cloth. The fiberglass cloth would vary in its combinations of ounces and layers for the decks. For example; I like to do strong laminating – on the bottom deck I use 1 layer of 6 ounce and a double layer patch over the fin boxes. This would make the fin box area 12 ounce. On the top deck, I use a double layer of 6 ounce on the entire deck. This would make the top deck 12 ounce.”

“The more solid one is the polyurethane and the bubbly one is the polystyrene.”

How long have you been building boards? Did you teach yourself?

“The first board that I ever made was with my brother and I was about 13 or 14 years old. This is my first memory of building boards and me helping him. ”

Where is your favourite spot to surf?

“Kalk Bay Reef.”

How do people approach you to design a surfboard?

“Word of mouth or Instagram.”

Do you get requests from people from overseas?

“A lot of my customers are foreigners. I do have a lot of South Africans who can afford my boards and who do want my boards but the majority are German, French, and Dutch tourists. I’ve been shaping for nearly 20 years, in that time I’ve made a wide variety of boards for a wide variety of people and nationalities.

Tourists come to South Africa for three months. They’ll arrive and order a board. Generally and depending on my workload they will get their board in about two to three weeks. They surf during their surf holiday and then take it back home with them. Sometimes they’ll order two to three boards, take them back home and sell off two boards that help pay for their trip.”

Do you test the boards or let your customers test them? And have people bought back a surfboard because it didn’t “work” for them?

“No. I’ve never had anybody come back to me with that issue. When I hand over the board I tell my customers that the board has taken two to three weeks for me to make but it needs another two weeks of curing time after I’ve glassed it. I tell them not to surf it because it will either get a dent or they could potentially break it in half.”

If you’d like to follow Lyndon Read on his journey shaping all sorts of boards for clients, then follow him on Instagram, with his handle, @lyndonreadsurfboards, or Facebook.

If you’re interested in picking up a new hobby or finding your passion in life, Stoked School of Surf offers various lessons for surfers of all ages. From surf camps in Cape Town, to Stand Up Paddling (SUP) lessons, we have it all. Get in touch to receive your stoked experience